Our Process Capabilities

U.S. Axle’s US-based manufacturing facility offers skilled operations, such as turning & milling, deep hole drilling & honing, induction hardening & tempering, as well as splining, cylindrical grinding, heat treating, shot-peening, and torsional presetting.

When it comes to axles, shafts, and cylinders, U.S. Axle is looking for your complex, multi-step, and integrated manufacturing challenges. Our world-class induction hardening, value engineering, and process experts will deliver to-spec and enhance your product and business performance. Let us show you why many of our long-term customers say that U.S. Axle provides improved delivery, performance, reliability.

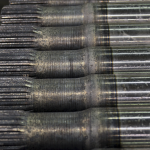

Induction Hardening

Precise. Custom. Strong.

We adjust our induction hardening and tempering processes to meet your precision needs. The method we prefer is more precise than typical flame hardening.

Induction hardening applications manufactured at U.S. Axle include drive, stub, and power transmission shafts… MORE ➙

Splining

Specialized. High Performance. Reliable.

When high torque loading is present, and the circumference load distribution is critical to good shaft performance, U.S. Axle utilizes a specialized splining application for drive, stub, and power transmission shafts… MORE ➙

Deep Hole Drilling & Honing

Unique. Durable. Experienced.

U.S. Axle utilizes one of the largest deep hole drilling machines on the East Coast, allowing us to almost exclusively craft these custom parts. This is how we consistently reduce costs and delivery time for our customers… MORE ➙

Cylindrical Grinding

Dynamic. Powerful. Exact.

U.S. Axle’s cylindrical grinding capabilities can be used wherever tight tolerances and high concentricity requirements are needed to ensure satisfactory bearing and seal life, taper fit integrity, and dynamic performance… MORE ➙

Turning & Milling

Hi-Tech. Efficient. Innovative.

At U.S. Axle, we have the capability of turning and threading deeper into the inner diameter of tubes, cylinders, and threaded tubes.

If you face a turning and milling challenge, we’ve probably engineered an applicable solution… MORE ➙

Metals

U.S. Axle focuses on using low to medium carbon steels in its manufacturing processes. These materials are typically are chosen to address particular production needs: alloyed steel can be used where heat treatment is utilized, while stainless steels are chosen where corrosion life is of the utmost importance.

We manufacture parts from: closed die forgings, open die forgings, steel castings, steel barstock, ductile metal barstock, ductile metal castings, and aluminum extruded bars.

Typical steel grades are 1018, 1045, 1141, 1541, 15B35, 4130, 41B30, 4140, 4150, 4320, 4340, 4820, 5130, 5140, 8620, 9310, 52100. We have extensive knowledge with hardening these steels as well.

U.S. Axle has long standing relationships with steel mills and warehouses to provide the most cost effective solution for your specific requirements. We also stock some grades and sizes.