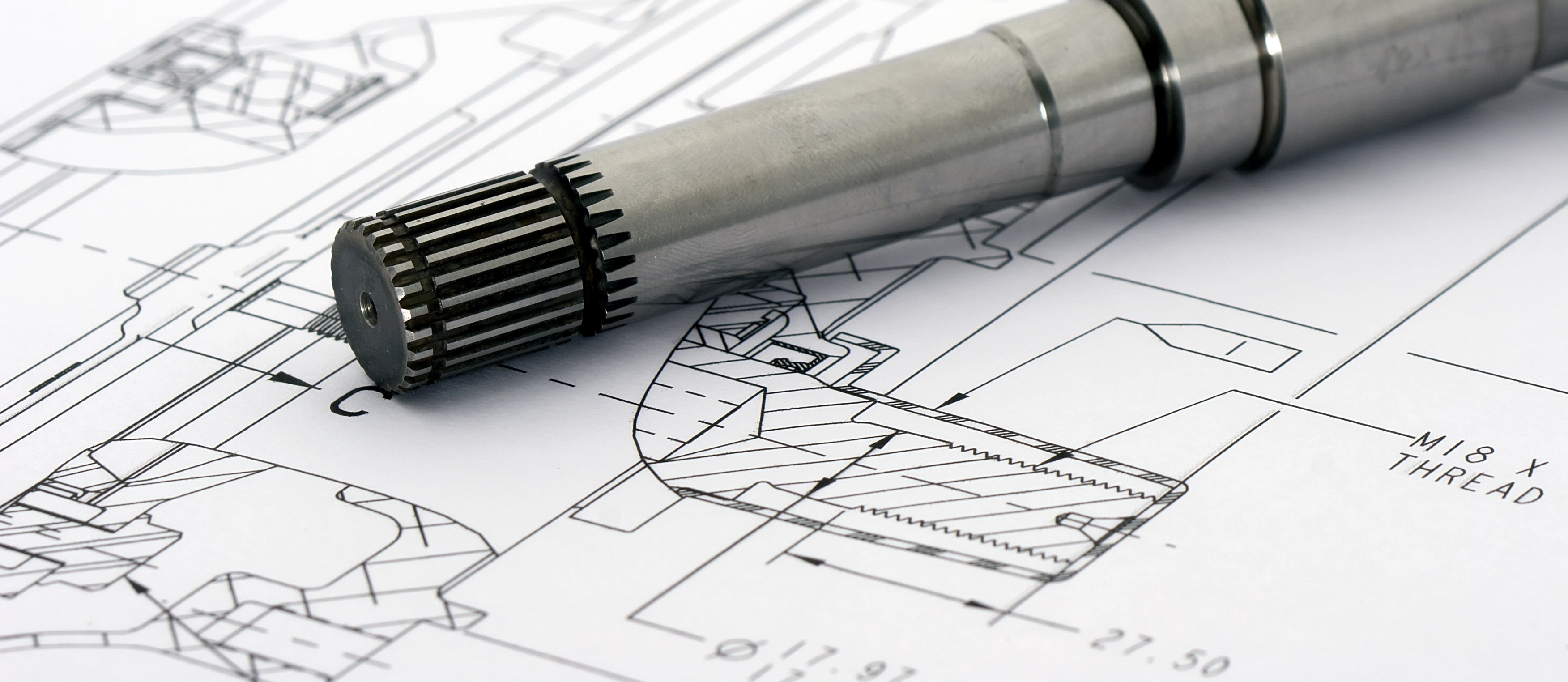

U.S. Axle uses its engineering and process expertise to work with OEMs to manufacture heavy equipment axles, shafts, and cylinders. Our Pottstown, PA facility is fully equipped to efficiently produce reliable, custom and individualized parts. And our integrated processes: machining/milling, induction hardening, deep hole drilling, honing and other related services are overseen by an experienced staff committed to excellence. For nearly 100 years, we have manufactured quality parts for OEMs in Agriculture, Construction, Heavy Trucks, Rail, Downhole Drilling Markets, and other industries.

If you have big ideas for the success of your business, start with U.S. Axle. We welcome your complex, multi-step, and integrated manufacturing challenges: including automotive, railroad car, carriage, off-highway driving, industrial, planetary, steel, steering, tractor, trailer, truck, tubular & undercarriage.

We focus on performance, reliability, and value to create purpose-built custom axle, shaft and cylinder solutions that enhance your company’s success.